APPLICATION: ZEOLITE IN CONSTRUCTION

Zeolite in concrete, mortar

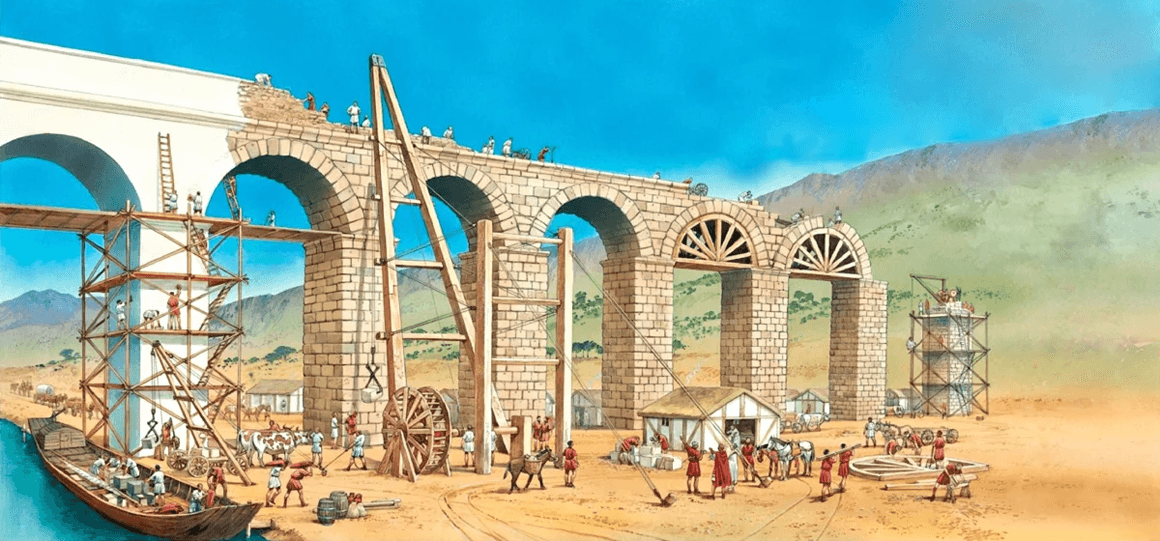

Natural zeolites were used as pozzolanic materials in construction 3000 years ago. In antiquity, zeolites were used with lime in mortars and concrete for construction.

The Romans used Neapolitan yellow tuff zeolites near Pozzuoli. In Italy it was used in the construction of aqueducts, public buildings and highways. The combination of lime and zeolite has shown excellent cementitious properties. For many years, natural zeolite tuffs have been used as cement pozzolans in Serbia, Germany, Italy, Bulgaria, China and Russia.

Due to the properties of zeolite, its high pozzolanic activity, zeolite was used as an active mineral additive in the production of durable, frost-, moisture-, acid-, sulfate-resistant high-strength concretes. Such concretes are used in the construction of hydraulic structures, as well as bridges, flyovers, port facilities.

It is known that the introduction of zeolite in an amount of 10-15% allows to reduce the consumption of cement and to use a binder of the optimal ratio in mortars and heavy concrete of class B15-B10. When an activated zeolite is introduced into concrete, fractions up to 200 microns in the amount of 10-20% of the mass of cement (M400, M500), plasticizers may not be used, since the zeolite gives high plasticity and workability of the concrete mixture. If, nevertheless, a plasticizer is used, then its consumption should be 0.3-0.4% of the dry mass of cement.

The introduction of zeolite into concrete allows increasing the grade of concrete up to 750-800 and the index of water resistance up to W14-20.

Zeolite, which has undergone thermomechanical treatment, can be used in the production of high-strength structural claydite-concrete of grades M300-M700. Expanded clay concretes of the above grades with the use of zeolite have a number of advantages over concretes without the use of zeolite – these are their high frost resistance, water resistance, crack resistance. In addition, they have a higher resistance to fire conditions than concretes with heavy aggregates. This is due to the close values of the coefficients of thermal expansion for the aggregate with the use of zeolite and concrete matrix. The result is increased operational reliability and durability.

The use of zeolite in solutions makes the solution warm, which allows you to remove the cold bridge when laying. The introduction of activated zeolite in the amount of 10% into the solution reduces the thermal conductivity of the solution mixture by 5-10 times. The solution becomes elastic, has a high water-holding capacity, does not stratify.

The use of zeolite in concrete and reinforced concrete products reduces the time and temperature of steaming. Zeolite is an internal agent for the care of concrete, absorbing and holding water in itself for a certain time, then gradually giving it to the cement, contributing to its complete hydration.

Benefits

01

Increases the strength of concrete

02

Increases water resistance

03

Reduces thermal conductivity

04

Increases workability and flexibi lity of the mortar

05

Increases frost, acid and sulfate resistance

06

High pozzolanic capacity

Need help choosing a zeolite?

Please leave your contacts, our manager will contact you as soon as possible and answer all your questions.